Conveyor Belt Rollers

Conveyor belt rollers are a fundamental component of industrial transportation systems. From mining to logistics, and from transportation to construction, these rollers are used across a wide range of industries to ensure the safe, efficient, and swift movement of large quantities of materials. The performance, durability, and efficiency of conveyor belt systems are largely dependent on the quality and proper use of these rollers. As a result, selecting the right rollers and maintaining them properly is crucial for the operational efficiency of businesses.

What Are Conveyor Belt Rollers?

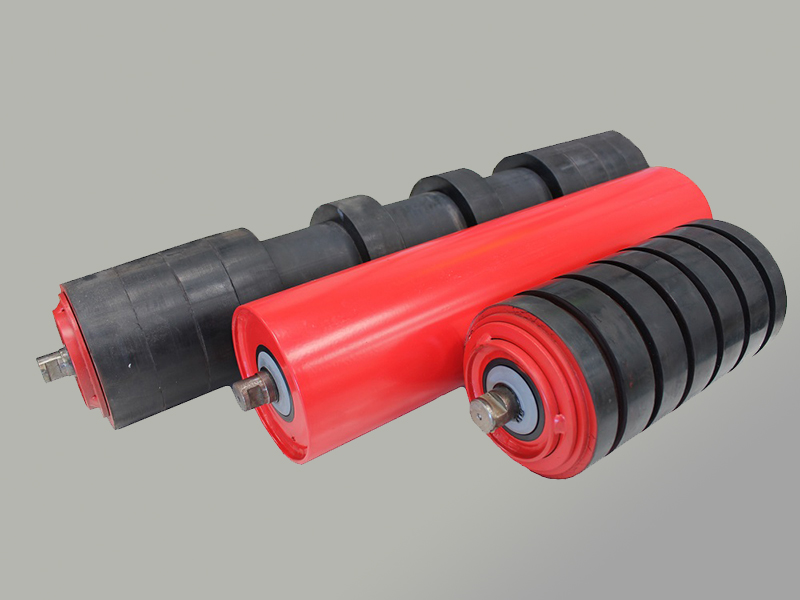

Conveyor belt rollers are rotating cylinders placed beneath conveyor belts, allowing materials to move smoothly across the belt. Typically made from durable materials like metal, plastic, or rubber, they support the movement of the conveyor belt, ensuring continuous and efficient transport. Rollers are available in various sizes and materials, depending on the load-carrying capacity and belt speed required for specific applications.

Importance of Conveyor Belt Rollers

Efficient Material Transport: Conveyor belt rollers enable the fast and uninterrupted movement of materials from one point to another. Properly functioning rollers help ensure the smooth progress of materials, preventing production delays and enhancing operational efficiency.

Durability and Longevity: High-quality rollers are designed to carry heavy loads and offer high resistance to wear and tear. This durability means the rollers require less frequent replacement over time, offering businesses significant cost savings.

Low Energy Consumption: Well-designed rollers reduce friction, allowing conveyor belts to operate with less energy. This not only leads to energy savings but also contributes to environmentally friendly production processes.

Reduced Maintenance Needs: High-quality rollers are built for long-term use, requiring less frequent maintenance. This helps keep production processes running smoothly without interruptions and reduces overall maintenance costs.

Types of Conveyor Belt Rollers

Carrier Rollers: Carrier rollers are placed beneath the conveyor belt to support the movement of materials. These rollers, with high load-carrying capacity, are commonly used in industries where heavy materials need to be transported.

Return Rollers: Used on the underside of the conveyor belt, return rollers facilitate the return movement of the belt. They are typically smaller than carrier rollers, as their primary function is to support the belt’s return rather than material transport.

Impact Rollers: These rollers are located at points where heavy materials fall onto the conveyor belt. Impact rollers absorb the shock of falling materials, preventing damage to the belt.

Self-Aligning Rollers: When the conveyor belt shifts out of alignment, self-aligning rollers help correct the belt’s position. These rollers are particularly useful in long-distance conveyor belt systems.