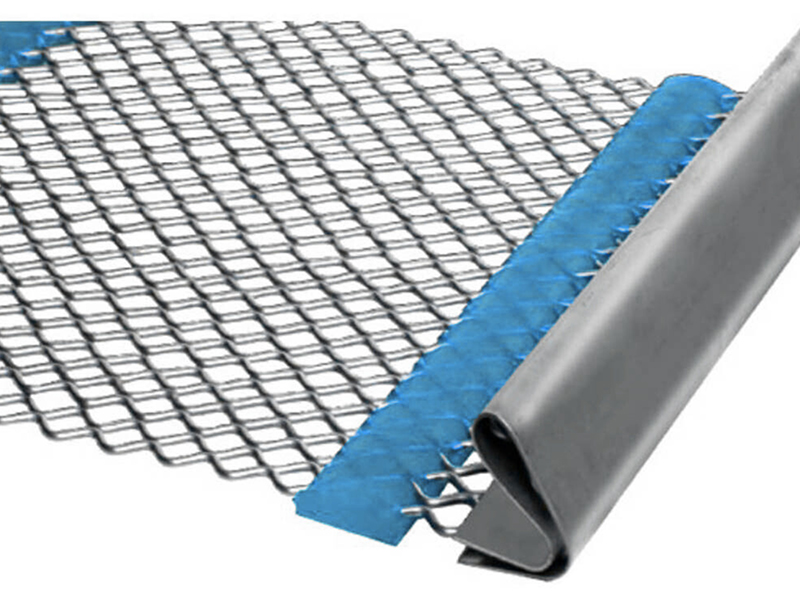

Flex Non-Clogging Sieves

Industrial screens play a vital role in many sectors, including mining, quarrying, construction, food, and chemicals. These screens are crucial for material separation processes, ensuring high efficiency and quality in production. However, traditional screens often face clogging issues, leading to production delays and increased costs. To address this challenge, Flex Anti-Clog Screens have been developed, offering durability and uninterrupted operation, thereby enhancing efficiency across various industries.

What Are Flex Anti-Clog Screens?

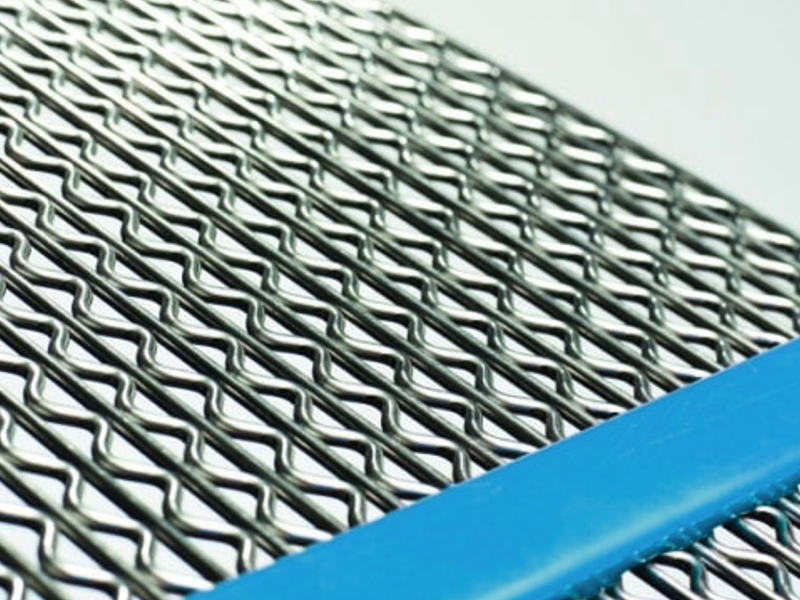

Flex Anti-Clog Screens differ from conventional metal screens due to their flexible structure, which significantly reduces clogging problems. These screens are typically made from elastic materials like polyurethane or rubber, allowing them to self-clean through vibratory movements. The elasticity of the screen ensures that materials pass through without clogging the openings, maintaining continuous material flow and minimizing the risk of blockage.

Advantages of Flex Anti-Clog Screens

High Resistance to Clogging: Flex screens effectively prevent the buildup of fine and sticky materials. The flexible design allows particles to pass through the screen without blocking the apertures, eliminating the frequent clogging issues seen in traditional screens.

Longer Lifespan: Made from wear-resistant materials, Flex Anti-Clog Screens have a longer operational life. This reduces the need for frequent replacements, leading to fewer production stoppages and lower maintenance costs compared to traditional metal screens.

Increased Efficiency: With clogging minimized, production processes can continue uninterrupted. This boost in efficiency saves time and reduces overall operating costs for businesses.

Easy Installation and Maintenance: Flex screens are generally easy to install and require less maintenance compared to conventional screens. Their flexibility and resilience against impact make them more durable and less prone to damage.

Applications of Flex Anti-Clog Screens

Flex Anti-Clog Screens are widely used in industries where material separation and classification are crucial. These sectors include:

Mining and Quarries: Clogging is a major issue in these industries, and Flex Anti-Clog Screens are particularly effective in separating fine and sticky materials.

Construction and Concrete Production: These screens enhance the efficiency of sieving sand, gravel, and stones in construction materials processing.

Food and Chemical Industries: They are used in the separation of powders and granules, minimizing the risk of clogging during material sorting.